Vapour Blasting

Motorcycle - Car - Boat - Truck - Aviation

Whether it's for for Antique - Vintage - Classic - Modern - Rally - Road - Race.

What do we vapour blast?

• Carbon Fibre

• Stainless Steel

• Rubber

• Chrome

• Steel

• Brass

• Fibreglass

• Aluminium

• Glass

• Plastics

• GRP

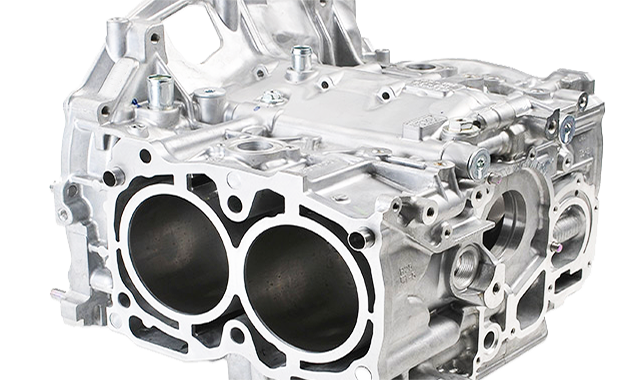

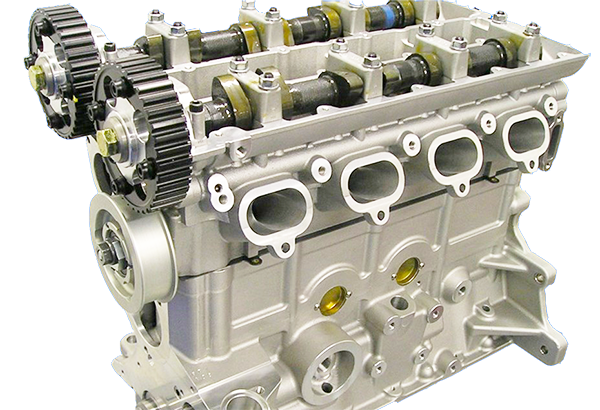

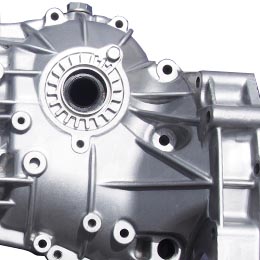

All metals can be process by Vapour Blasting with excellent results. Aluminium castings in particular look “like new” after this process.

The peening effect of vapor blasting actually seals the microscopic pores on the surface, the part will not absorb grease and dirt like a dry blasted part will. Surfaces are not affected, precision tolerances, such as bearing fits and piston size will not be changed.

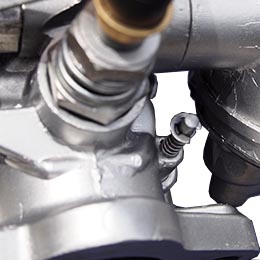

Vapour blasting uses water and mildly abrasive media to clean metal surfaces without actually wearing away any of the metal - unlike sand-blasting which is a far more destructive process.

The water buffers and lubricates the particles on impact allowing very fine finishes to be produced without damage to the component.

The end result is a far finer finish and no abrasive media is left behind because it is all washed away with the water, to restore components to a "like new" condition, producing a smooth, satin finish.

Vapour blasting is also great for surface preparation for bonding, polishing, welding, or coating of parts & components.

Cleaning the topography of the surface this provides an excellent surface for plating.

The flushing action of combined water and abrasive allows optimal surface cleanliness and preparation for final metal plating - Nickel, Chrome, Brass or Silver.