Vapour Blasting

Frequently Asked Questions

What is the difference between Vapour blasting and aqua blasting?

Vapour blasting, Wet Blasting and Aqua blasting are the same thing.

Does it matter if my car part is covered in oil and grease?

Yes it should be degreased first, you can buy many engine de-grease products which are easy to use, if we have to degrease the item this is charged as an extra.

Can I wait whilst you vapour blast my parts?

Yes, depending on the size of job it may be possible for you to wait, different jobs require different media so they tend to be vapour blasted in batches, so please make sure you phone first to check that we can fit you in.

Which blast media does Vapor Blast Canterbury typically use?

We generally use glass bead or aluminium oxide of various sizes to suit the job(s) but can use custom media, together with machine setup via pressure and flow changes, to achieve any particular finish the customer requires. Contact us to discuss your requirements if such a bespoke setup is required.

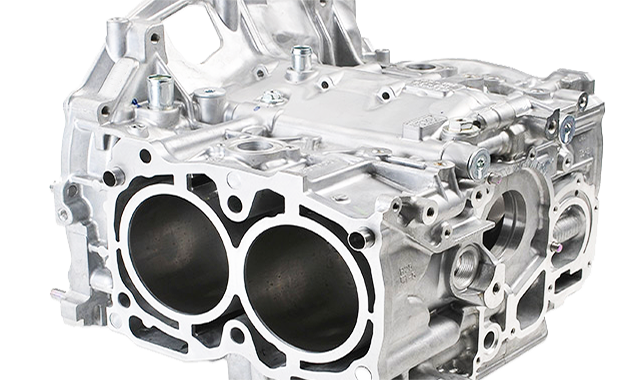

What is the size and weight limit for processing parts?

Most disassembled motorcycle/car engine, suspension and other components can be handled in the 1200mm (Interal Dimensions H 1200mm D 700mm W 1150mm) blast cabinet and a weight up to 150kg.

Why vapour blast instead of conventional sandblasting?

Vapour blasting is a far less aggressive form of blasting in comparison to dry blasting, working just as effectively and with a better finish. Vapour blasting does not allow for media to be impregnated into the component, nor is there any dust created by the break-up of media.

What preparation must I do before sending parts to be vapour blasted?

Degrease parts; remove gaskets and gasket sealer as well as possible. Disassemble components, remove all ball, needle or roller bearings, if left in they may require replacement prior to engine assembly. Bushings and plain bearings can remain in-situ. Carburettors must be completely disassembled; all gaskets, jets & floats etc. removed before being vapour blasted. You will be need to obtain and replace any O-rings or gaskets before you re-assemble them.

Will it erode metal and affect dimensions or tolerances ?

No, one of the benefits of vapour blasting is that all critical surfaces and dimensions of components remain unchanged.

What do I need to do after I get my parts back from vapour blasting before they can be used?

Whilst every care is taken to ensure there is no media remaining in your cleaned parts, we do advise that you rewash all parts again before fitting and use a good long-life anti-corrosion/lubricant spray on exposed external parts.

Do you give trade discount?

Yes, give me a call.

Do you give discounts for clubs?

Yes, give me a call.

What payment methods do you accept?

We accept cash or bank transfer.

I still have more questions I need to ask?

Simple give us a ring or use the contact page, we will give you advice specific to your job requirements.