Vapor Blast Canterbury for Vapour Blasting

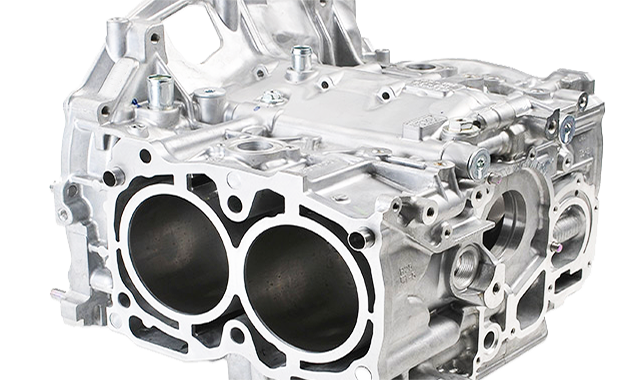

For High Quality Finishing. Vapour blasting or wet blasting is non-destructive which makes it an ideal process for cleaning many components to the highest standard and produces a smooth, satin finish.

Based near Cust, close to Christchurch, Rangiora, Kaiapoi, Amberley, Rolleston, Ohoka, Oxford and Methven.